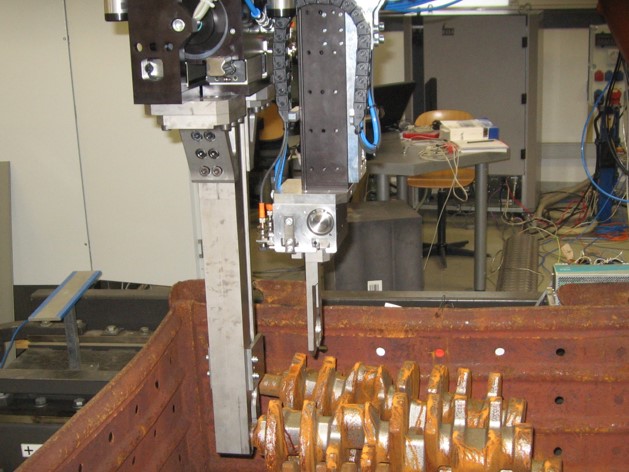

Crankshaft depalletizing

Robot solution for depalletizing crankshafts in forges and foundries demonstrates its class

In the forging industry, workpieces are often stored partially or unordered in load carriers until further processing. Anyone who wants to automate the handling of the parts (e.g. crankshafts) faces a complex task. He must ensure that the position and orientation of the workpieces in the carriers are recognized, the parts are gripped and fed to the processing machine.

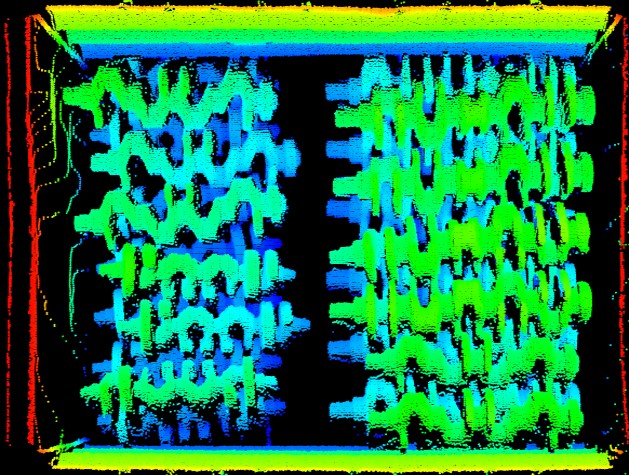

AROTEC has met this challenge and developed an innovative robot system for forging and foundries: it demonstrates its reliability at a forging company, among others. The core of the robot application is the 3D object recognition software ART-3D. This software package ensures precise detection of crankshafts in a Heson vessel. In combination with the intelligent crankshaft gripping system, it ensures efficient handling. In addition, the 3D object recognition software ART-3D ensures that the robot and gripper do not collide with the environment. For the customer, this solution means a significant increase in efficiency.

You want more information about the robot system? Get in touch with us here.

Talk to us now about robot-assisted automation of your production processes.

We also develop a customized robot system for you. No matter how complicated your requirements may be. No matter in which industry you are active.