Crucible palletizing and depalletizing

Crucible palletizing and depalletizing

AROTEC automates crucible palletizing and depalletizing at a chemical company

AROTEC automates jar palletizing and depalletizing at a chemical company

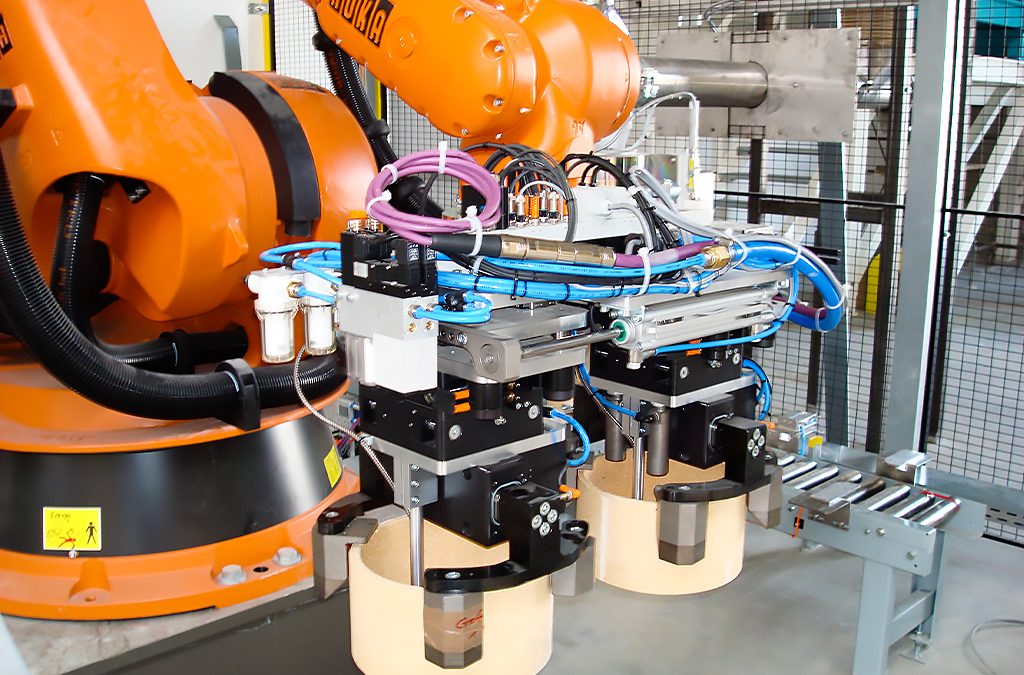

In the chemical industry, many tasks are still performed by hand. In doing so, the personnel often work in a polluted environment that is hazardous to health. AROTEC has also set new standards in this area. For a paint manufacturer, the company developed robotic cells for the automatic handling - i.e. depalletizing and palletizing - of crucibles. The system has proven itself in practice.

In the robot applications, the position of the crucibles is determined by means of a 3D vision sensor (or from a point cloud): The crucibles are detected with the help of the 3D object recognition software ART-3D after localization with a flexible gripping system in a multiple grip. Before filling, the crucibles are depalletized from a kiln car. And palletized again after filling. What previously had to be done by people under difficult conditions now runs fully automatically.

We would be happy to inform you in more detail about the robot system. Just send us a message.

Talk to us now about robot-assisted automation of your production processes.

We also develop a customized robot system for you. No matter how complicated your requirements may be. No matter in which industry you are active.