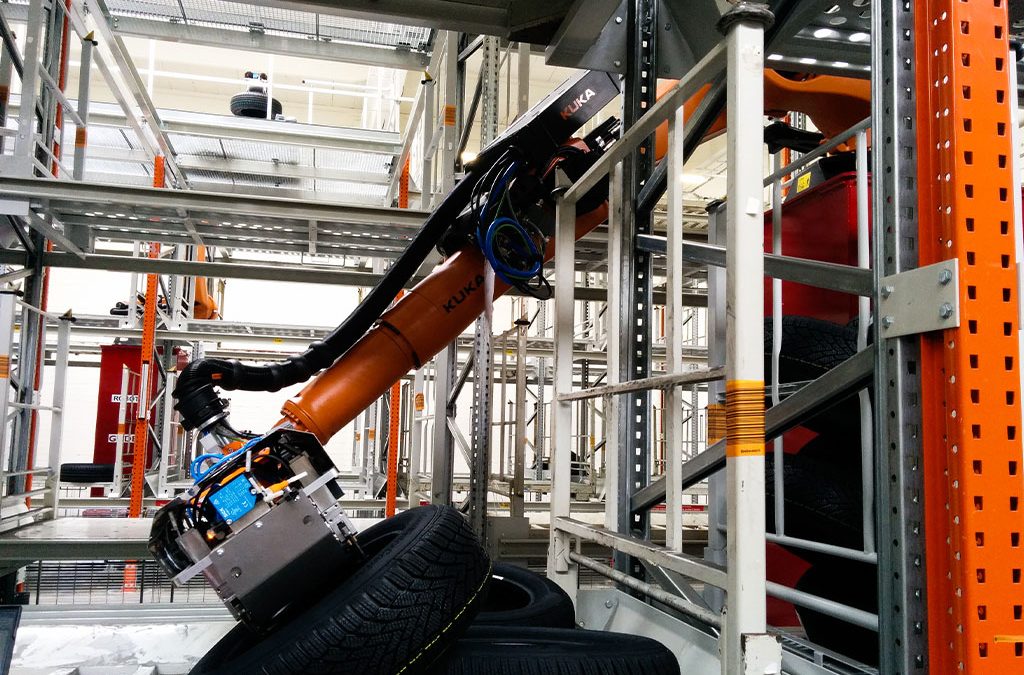

Tire palletizing

AROTEC automates tire palletizing with the help of robots

Tires are still largely palletized by hand today. The reason: loading the pallets optimally is difficult due to the complex design of the palletizing patterns. With PALGO@Tire AROTEC has developed a tire palletizing software that solves this problem. The program is used in numerous tire plants worldwide.

In the robotic automation solution, more than 800 different types of tires are palletized by 6 robots after the tire palletizing software PALGO@Tire tire palletizing software has determined the optimal tire palletizing pattern. AROTEC also integrated a plant control computer into the plant concept. It coordinates the 6 palletizing robots and is connected to further logistics systems such as material flow computer and forklift control system. The robot-based automation solution has significantly increased the efficiency of tire palletizing.

The solution at a glance:

- Fully automatic tire palletizing line with 6 robots mounted on a linear axis, thus engaging several pallets.

- No pre-sorting of tires required (delivery in a mix of grades)

- Capacity: approx. 21,000 tires per day

- Hoop palletizing pattern: chain (rick-rack and chimney pattern).

- Over 800 different types of tires, including up to 120 tires at a time.

- No tire deformations and pallet overruns

- Tire weight up to 30 kg, tire size from 14-24 inch

Talk to us now about robot-assisted automation of your production processes.

We also develop a customized robot system for you. No matter how complicated your requirements may be. No matter in which industry you are active.