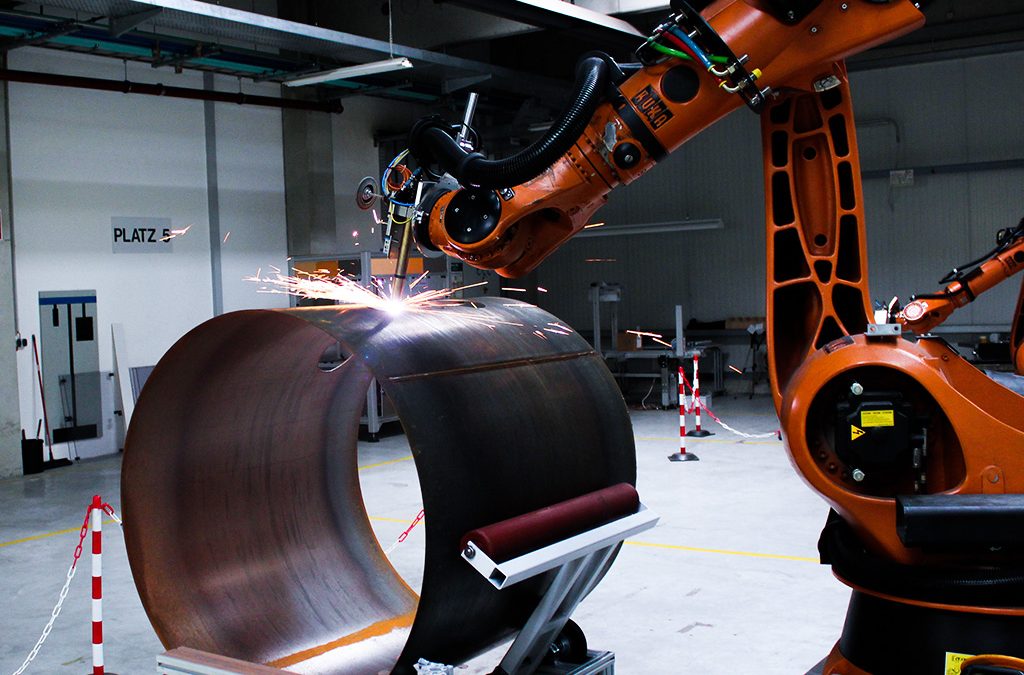

Robot assisted plasma cutting

Offline programming system VMP enables economical contract manufacturing of storage containers

For a tank manufacturer, AROTEC automated cutting and marking on storage tanks using plasma cutting technology.

The special feature of the solution: The first-time use of the Visual Motion Planner (VMP)which makes contract manufacturing economical in the first place!

In the plant, robots and plasma cutting torches are used to make marks on the jackets and bottoms of storage containers and cut the required openings.

The storage bins with the web and process data are stored order-specifically via a customer-specific interface (GUI) in VMP generated. Afterwards, the data is checked in the simulation, tested and corrected if necessary. Finally, the data is exported and stored in a database.

The robot controller can now retrieve the job data and process it directly in a parameterized robot program.

Practical test passed: With VMP production times can be reduced by over 50%!

And: VMP is suitable for all path-guided robot applications such as cutting, welding or gluing!

We will be happy to inform you in more detail about the solution for. Get in touch with us here.

Talk to us now about robot-assisted automation of your production processes.

We also develop a customized robot system for you. No matter how complicated your requirements may be. No matter in which industry you are active.