Efficiency turbo for your tire palletizing

The efficiency turbo for your tire logistics

Palletizing and depalletizing tires into and out of a load carrier by hand is hard physical work that in the long run is not only detrimental to the health of your employees, but also proves to be extremely inefficient.

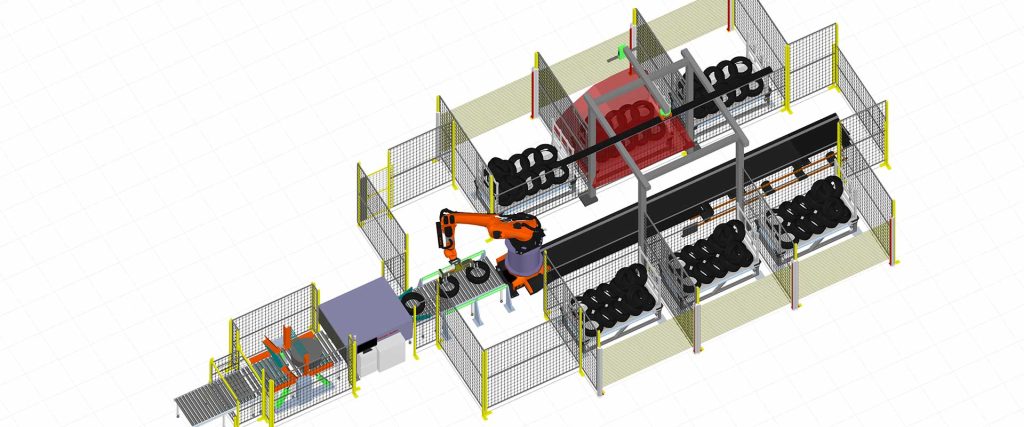

Nevertheless, this activity is still mostly performed by humans. AROTEC helps you to fully automate your loading and unloading processes or tire palletizing in incoming goods and tire depalletizing in outgoing goods with the TirePal and TireDepal robotic systems.

AROTEC@Tire - A real efficiency turbo for the logistics of your tires! Our specially developed software packages PALGO@Tire for tire palletizing and DEPALGO@Tire for tire depalletizing represent the core of our diverse automation solutions.

Our automation solutions for tires:

- Lower your costs

- Increase your throughput

- Increase your quality

- Are user-friendly, easy to use and offer maximum transparency.

- Do not require specific (robot) qualification

- Process a wide range of tires, different tire patterns and load carriers

- Enable automatic tire identification by reading the DOT/DOM

AROTEC develops turnkey automation solutions for the palletizing and depalletizing of tires.

AROTEC automates the palletizing and depalletizing of tires into or out of a load carrier

When palletizing tires into a load carrier according to a chain, chimney or roll pattern, the in-house developed PALGO@Tire tire palletizing software forms the heart of AROTEC's robot-based automation solutions. Just at the beginning of this year, the tire palletizing software was thoroughly revised so that it now features a browser-based graphical user interface.

In addition to simpler operation/ greater ease of use, it offers numerous new features in tire pattern generation, processing and management compared to the previous software. In interaction with the latest generation of the tire measuring station, even higher packing densities can be achieved.

When depalletizing tires from a load carrier, the in-house developed DEPALGO@Tire tire depalletizing software forms the core of AROTEC's robot-based automation solutions. Using a 3D vision sensor or based on the point cloud, the tire poses within a load carrier are reliably determined, the relationships of neighboring tires are examined, so that tires can be unloaded in pairs (i.e. simultaneous removal of two tires in one robot cycle) by one robot.

We have recently been able to add another important component to our robot-based automation solutions for tire palletizing and depalletizing - the automatic identification of tires or wheels.

With the station, the tire identification number (TIN or DOT/DOM), the manufacturer's name and the imprinted tire size can be automatically recorded with high reliability and transmitted to the higher-level control of the automation system. In the case of directional tires, the direction of travel can also be determined. This information ensures that the "right" or "desired" tire is always placed in the "right" position in a load carrier or transferred to a downstream process station.

Tire localization unit

Industrial robot with end effector

Tire Identification Unit

Tire turning unit

Pallet storage space