Find out how AROTEC masters the art of mixed palletizing!

January 10, 2024

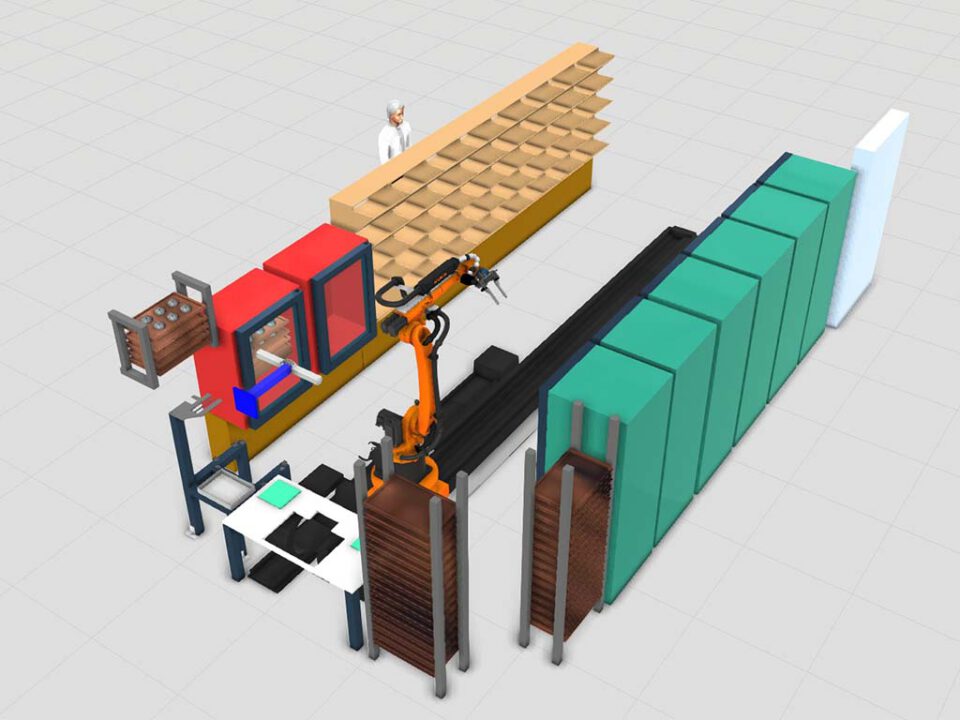

Research project at AROTEC

February 8, 2024Efficient automation by AROTEC Robotik und Automation GmbH

In the ever-changing world of industrial automation, efficient router placement in systems with SDA (Software-Defined Automation) is becoming increasingly important. Companies are striving for ever faster production processes, higher precision and lower manufacturing costs.

AROTEC plays a decisive role here by developing innovative automation solutions that meet the requirements of modern manufacturing operations.

Milling is a key element in many manufacturing processes, especially in metal and woodworking. The aim is to machine workpieces precisely in order to create complex shapes, recesses and surface structures. Here, the accuracy of positioning and the repeatability of movements are of paramount importance. Traditionally, this has been a manual process, but it has become increasingly impractical due to inefficiency, errors and high labor costs.

With the introduction of SDA, the possibilities of production automation have expanded dramatically. SDA enables the precise control and coordination of machines and robots using advanced software that reacts in real time. This has opened the door to optimized milling assembly, where robots and automation solutions play the main role.

AROTEC has made a name for itself as a pioneer in the development of customized automation solutions. With a strong focus on SDA and robotics, they have managed to help companies in a wide range of industries revolutionize their manufacturing processes.

Your solutions for milling assembly at SRS-Stahl GmbH are characterized by exceptional precision, flexibility and efficiency. Our robots are able to process workpieces in the shortest possible time and with remarkable accuracy. By integrating advanced sensors and camera systems, they can adapt to different materials, shapes and sizes.

The precise movements of AROTEC robots ensure the consistently high quality of the manufactured workpieces. This minimizes rejects and increases customer satisfaction. By automating milling assembly, companies can increase their production speed and shorten production times. This leads to increased overall efficiency. Automated processes reduce the need for manual labor, which leads to significant savings in labor costs. In addition, higher machine utilization can be achieved. AROTEC's SDA-oriented solutions are flexibly programmable and can be easily adapted to changing requirements and production patterns. Milling assembly at SRS-Stahl GmbH by AROTEC undoubtedly represents a groundbreaking innovation in production automation. Thanks to the company's advanced technology and extensive know-how, companies can optimize their manufacturing processes and gain a competitive edge.

The combination of precision, efficiency, cost reduction and flexibility makes AROTEC a strong partner for those who want to be successful in modern manufacturing.

Stay up to date with the latest developments and solutions from AROTEC by following the company on LinkedIn. Be part of the ongoing digital transformation and benefit from efficient, reliable and future-proof process communication at AROTEC.

Thank you for your interest! Please do not hesitate to contact AROTEC if you have any further questions or require additional information.